Singapore | 2020-23

Research Project

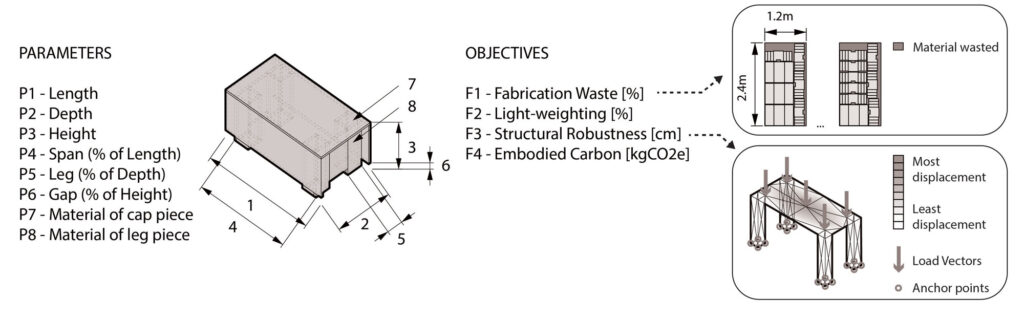

To produce many units of furniture with minimal waste, optimal robustness, and good potential for reuse is challenging design problem to optimize without computational support. Over a multi-year period this research project redefined circular economy design goals and frameworks as optimizable metrics and objectives and implemented these to refine a series of furniture designs.

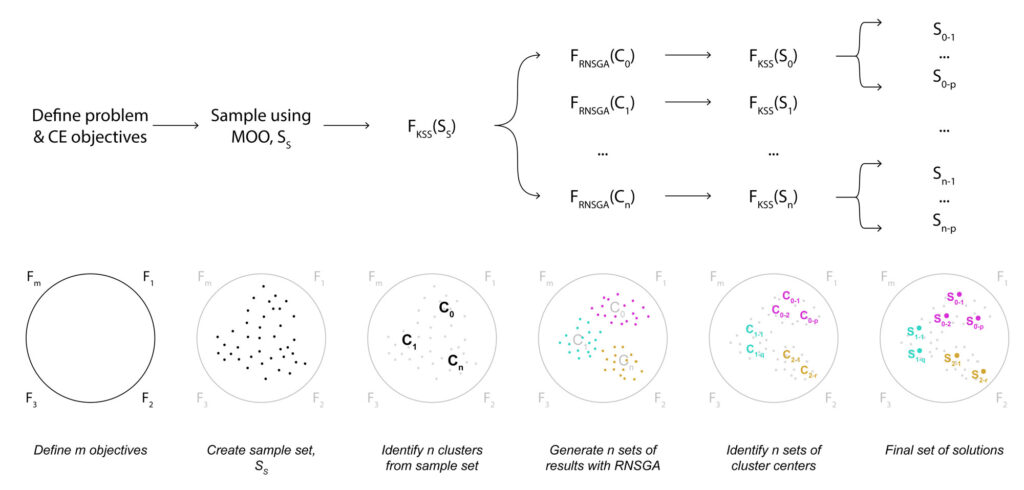

Extending beyond the application of evolutionary multi-objective optimization, this research ultimately implemented automated clustering of result sets to identify families of best performing solution types which could be returned rapidly to a designer with minimal tuning of the optimization process.

Publications

IJAC 2023, “Exploring a Circular Economy Solution Space”

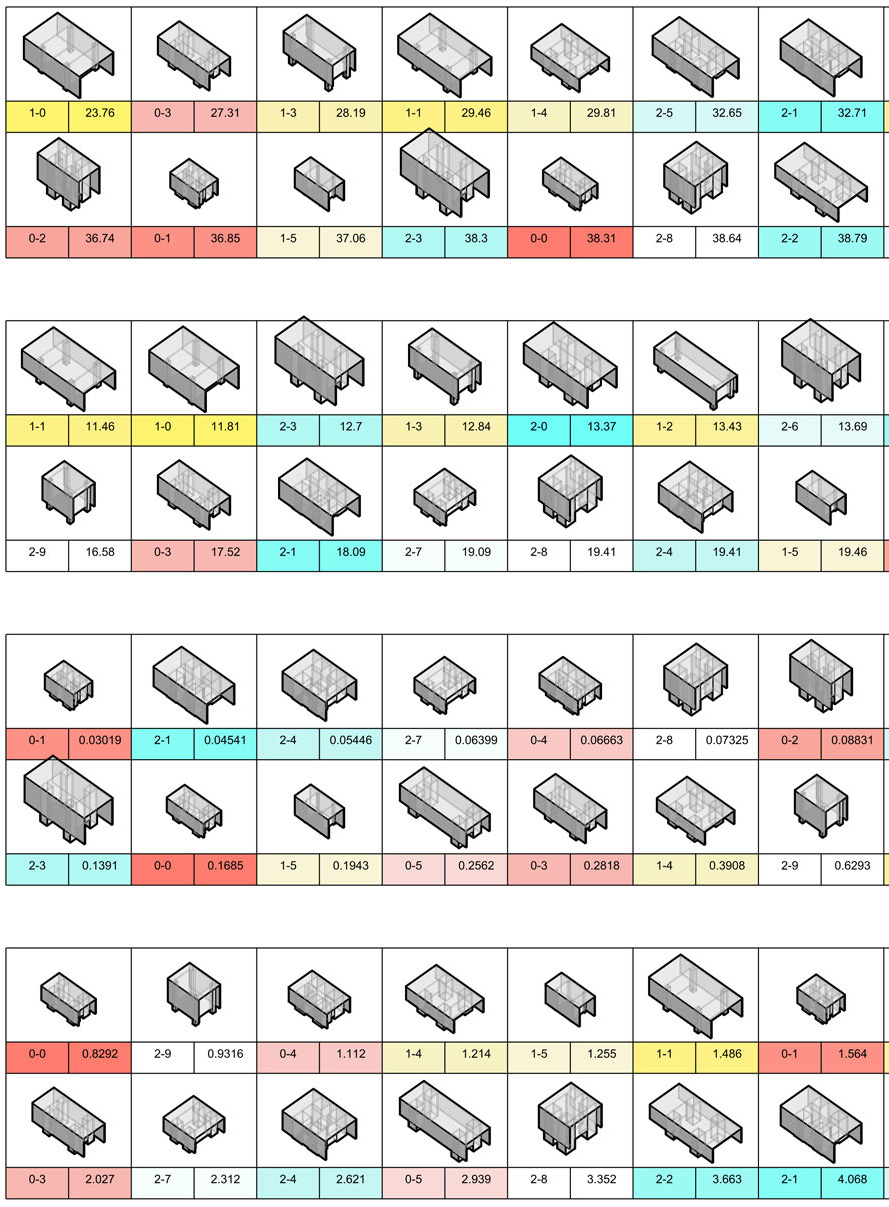

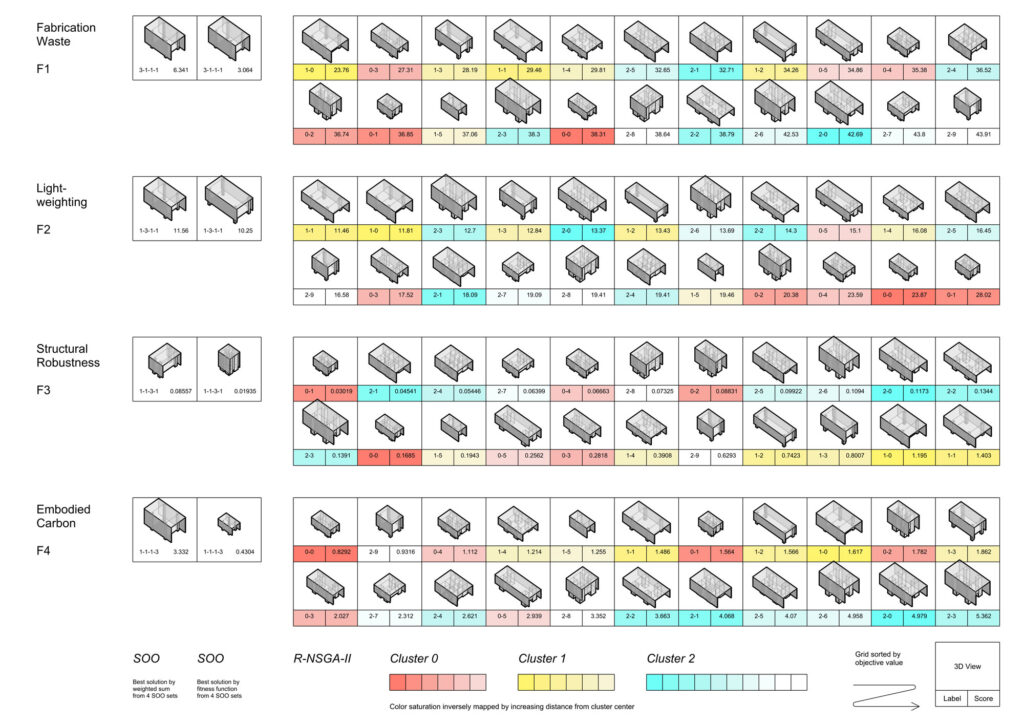

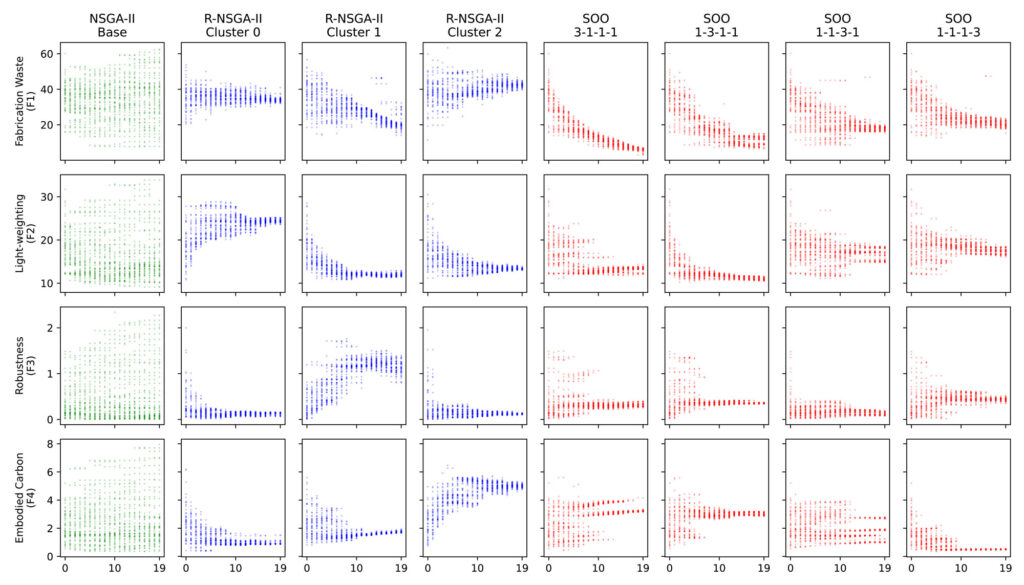

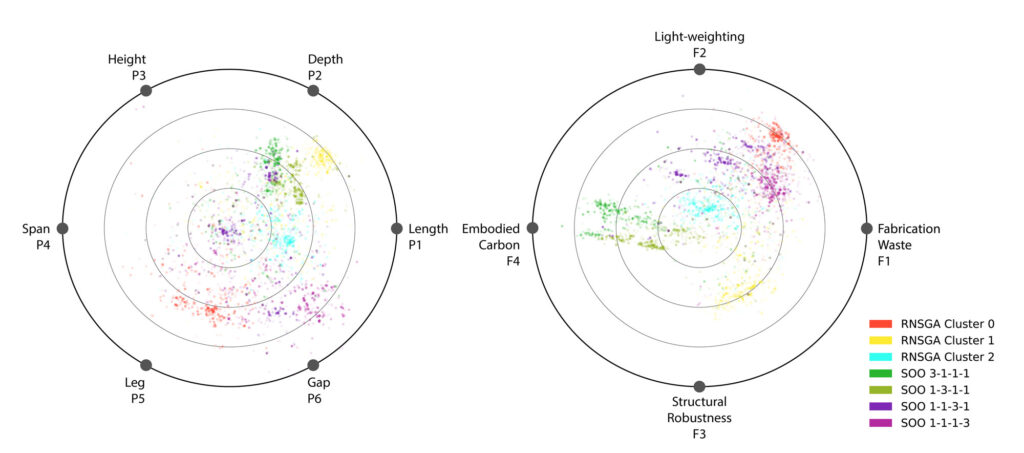

Design for circular economy is complicated by tradeoffs between objectives for different lifecycle phases. For example, we can reduce consumption of material overall, but this may come at the expense of product robustness and reusability. By defining a range of quantifiable objectives corresponding to each lifecycle phase, this research seeks to provide a more comprehensive computational assessment of circular economy product designs. The image above categorizes the outputs of an optimization run based on three automatically identified ‘typologies’ which are then targeted for further optimization with a reference point optimization algorithm (RNSGAII).

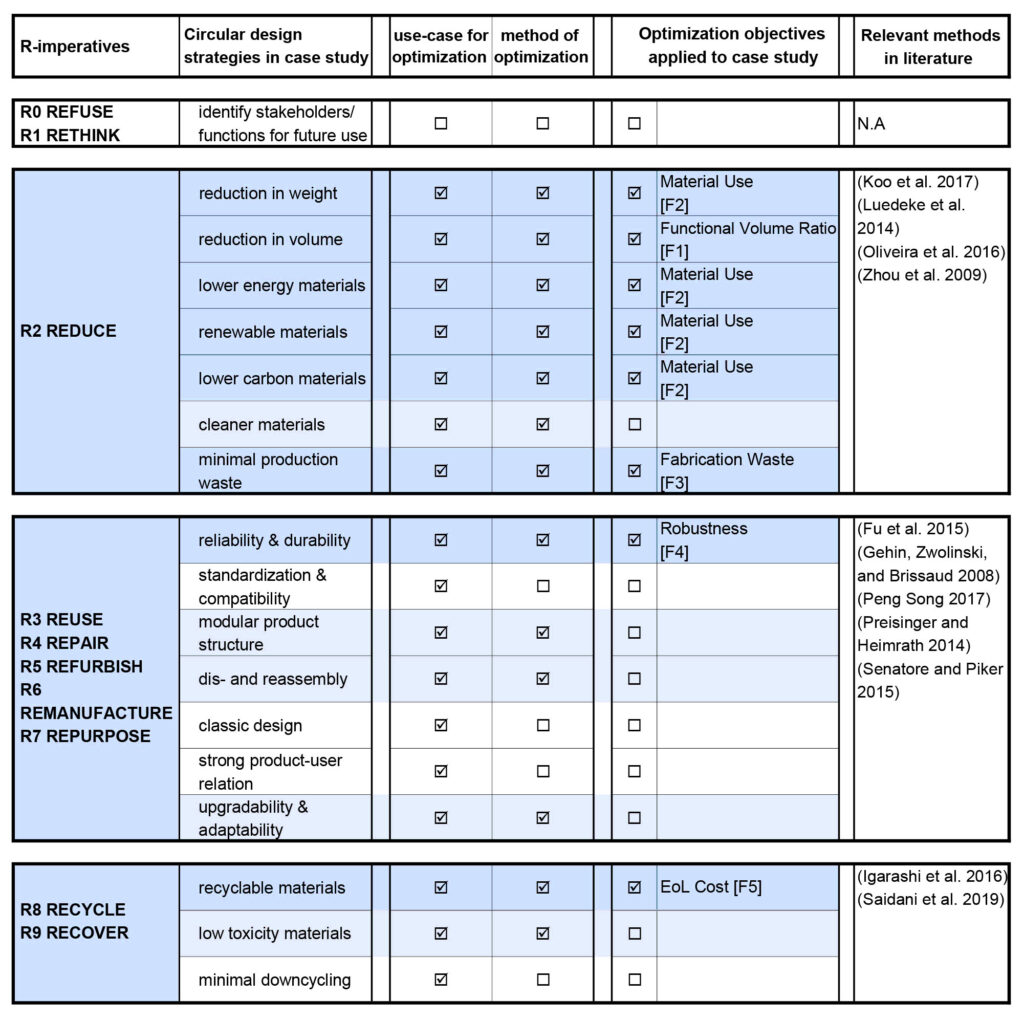

In the first phase of this research project we surveyed existing assessments for circular economy (CE) products. We also review CE design frameworks like the 9R framework, and a large range of design strategies for CE. The table above summarizes which CE strategies for CE are open to quantifiable assessment and optimization. Among these quantifiable strategies we sought examples of previous optimization research, and developed our own optimization model which we applied to our furniture design case study.

We built multiple versions of an optimizable model of the furniture case study, building in representations relevant to final design characteristics, structural performance, fabrication and folding/ unfolding.

In a second phase of the research we compared methods of optimizing models for circular economy. We studied reducing or combining the number of optimization criteria. However, the presence of conflicting criteria meant that no single best result could be identified. In response to this challenge we implemented an automated search function which first clustered results into ‘types’ and then targeted the best design options within these types.

These automatically targeted design search resulted not in greater optimization efficiency in comparison to multi-objective optimization (see results in blue above.

The automatically identified clusters presented visually distinct design strategies for circular economy products, while generating optimal results.

These design tools should assist the creation of a new generation of products, which minimize material consumption in fabrication, can be reused many, many times, are easy to remanufacture, and eventually when they reach end of life can be easily recycled with minimal environmental impact.

PI F Peter Ortner

PhD Student Tay Jing Zhi

Funding

SRG: Design for Circularity and Resilience