SUTD Architecture and Sustainable Design

Option Studio 2021

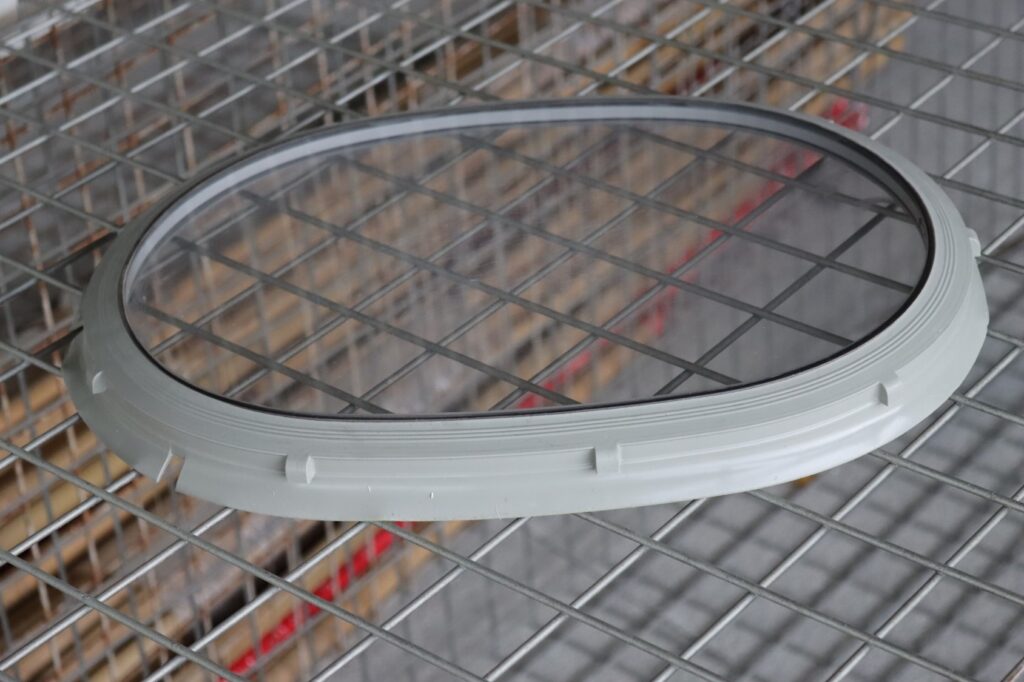

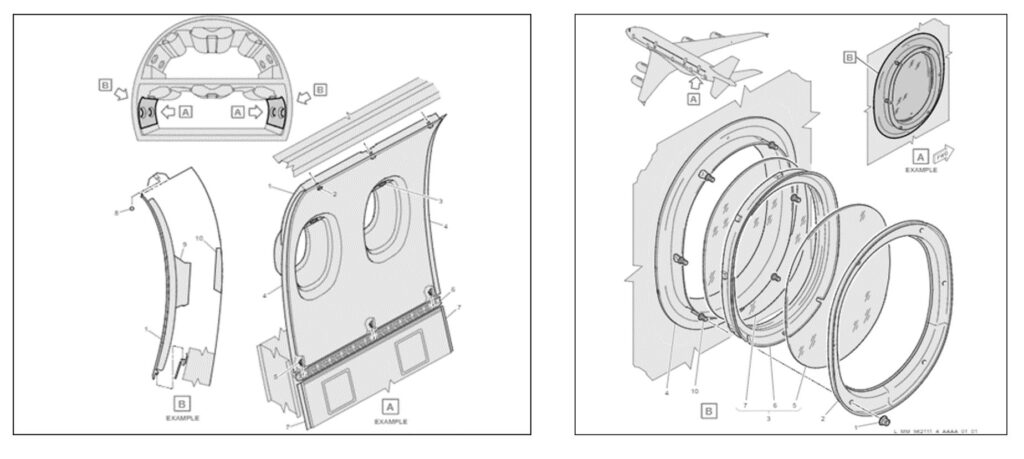

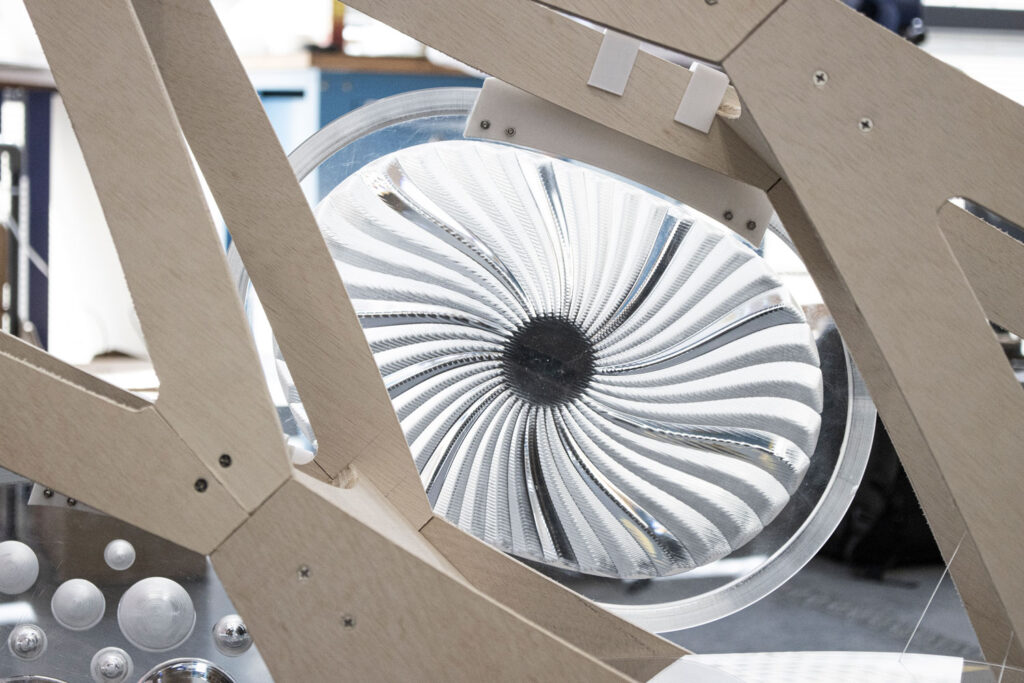

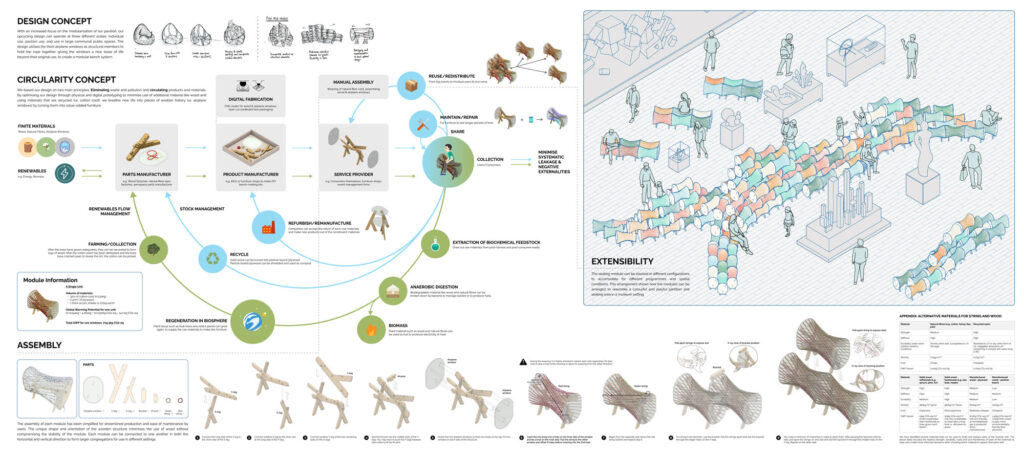

In partnership with Singapore Airlines this studio challenged undergraduate architecture students to upcycle components from a retired A380 as elements within an architectural pavilion. After a round of investigation and site visits with SIA the A380 windows were selected for upcycling as elements that would not otherwise be recycled or reused.

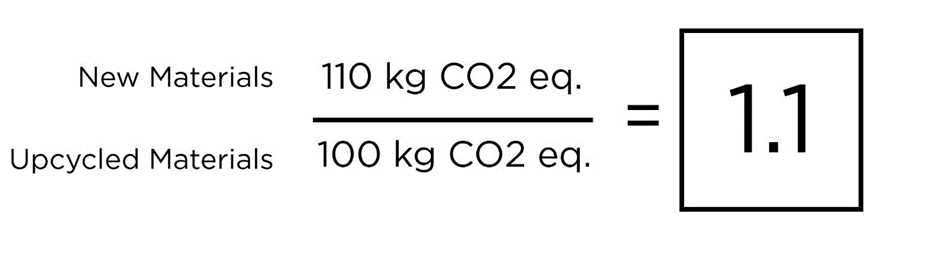

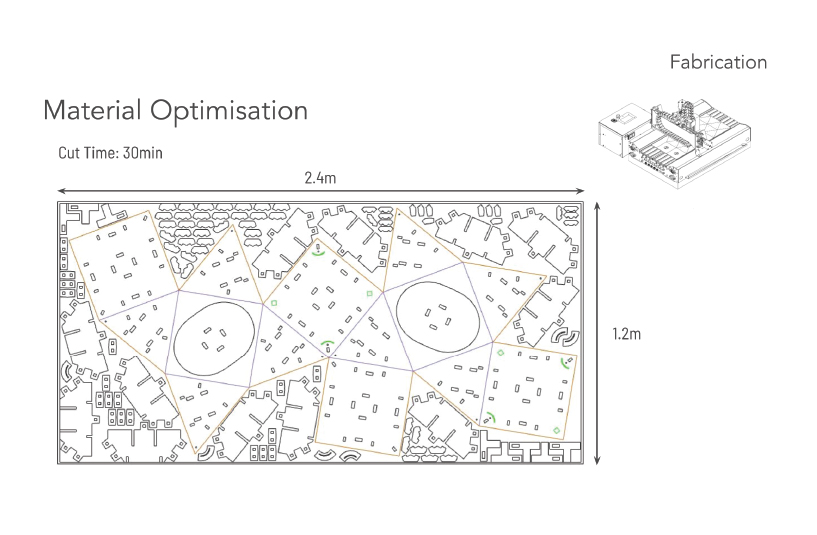

The studio aimed to minimize the global warming potential (GWP) of any new materials added into the pavilion design. The use of digital design and fabrication techniques was required to not only conceive designs, but also predict their performance and environmental impact.

<Programme>

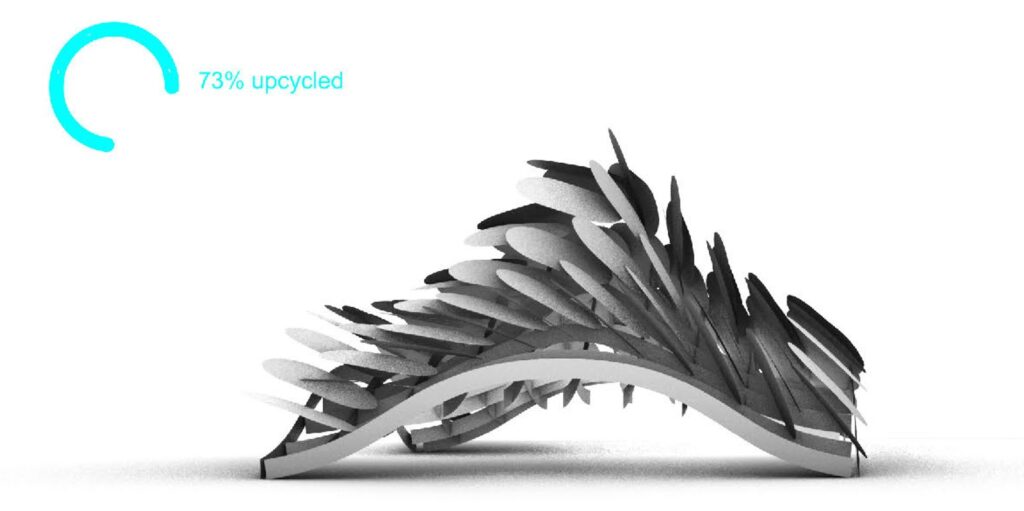

Students proposed an architectural pavillion, fitting within a 3x3x3 cube, that incorporated the upcycled components into a mass-customized and digitally fabricated architectural assembly.

The construction was required to approximate the technical systems of an architectural façade screen with repetitive cladding components, mass-customized structural components and a system of fasteners and brackets connecting the two.

The overall form, programme, and reuse narrative for the project was open to creative re-interpretation by students, with possibilities including but not limited to exhibition display for the national competition (Wunderkammer), study nook, seating, shading, sculpture, etc. Use cases could incorporate the idea of didactically sharing with visitors on sustainability, circular economy, Singapore Airlines, aviation. Students may suggest display materials to be included.

<Digital Design, Sustainable Design Workshops>

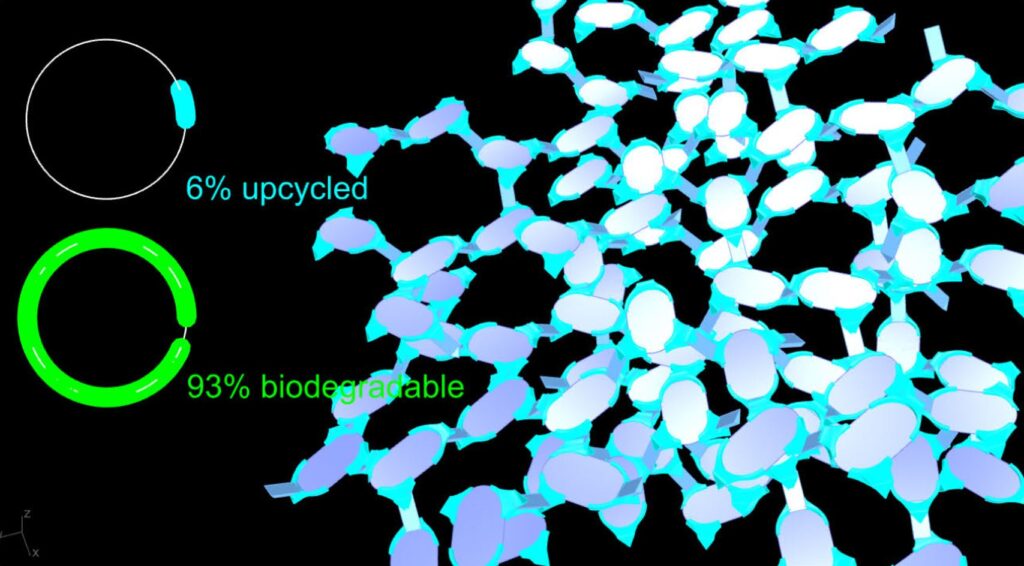

Workshopping of the design was addressed with two approaches: a bottom up approach sought to first define a component assembly and explore its possible aggregations;

whereas a top-down approach first defined a desired overall form, and then sought to subdivide it into components.

In each workshop the environmental impact of the design was tracked dynamically with measurements of the mass ratio between upcycled materials and new materials. Later in the term this tracking was updated to track GWP ratio instead of mass ratio.

<Fabrication>

The Upcycle Studio emphasizes fast prototyping. Students will be given fabrication training in the beginning of the term. In pairs of two they will produce a single module prototype for midterm.

Students were trained to use the laser cutter, water jet, zund cutter, and CNC router at the SUTD Fabrication Lab.

<Design Evaluation>

Criteria upon which the designs were be judged:

- REDUCE: Creatively minimizing material waste during pavilion design and fabrication.

(How do you use cut-offs, or other manufacturing waste? Can you minimize the embodied carbon of your completed pavilion, or some other metric (biodegradability)? - REUSE: Creatively maximizing longevity or reuse of the pavilion.

(Does the pavilion serve a clear purpose, or is it able to accommodate many potential uses?, can it form an emotional connection with its users?, is it robust enough to sustain many cycles of use?) - RECYCLE: Creatively minimizing environmental impacts of the pavilion at end of life.

(How easy is it to disassemble, recycle, decompose, or other? Will it generate waste at the end of its lifecycle, or can its materials become ‘food,’ for new products.)

Credits:

Studio Lead: Peter Ortner

Students: Joshua Ng Kay Wern, Kuan Yi Heng, Ryan Chua Jie Jian, Rachel Cheah Jiawen,

Photography: Peter Ortner

Thank you to Singapore Airlines (SIA) for your kind sponsorship!

Thank you to guest critics: Andrei Gheorge; Michael Budig; Erwin Viray; Ronald Lim; Andrew Lee